Projects in industry

The Institute carried out a large amount of work on the development and implementation of technologies for reducing energy consumption and reducing emissions of toxic substances and greenhouse gases in the environment in the processes of heat energy production.

Among the developments of the Institute new technologies and equipment for reducing the formation of nitrogen oxides in the process of combustion burned twice with the possibility of further refining; to reduce emissions of sulfur oxides twice by the semi-dry method; cyclophilic filters, including the possibility of a built-in sleeve filter, for dust removal with a coefficient of 99,9%; technology of combustion of organic substances in ventilation emissions; new generation hot water boilers (0.63 and 2.0 MW); heat recovery, air heaters; modernized podium emitting gas burners; intensification of furnace heat exchange; improvement of technology of combustion; reduction of emissions of toxic substances and greenhouse gases into the environment; reduction of energy consumption in the process of production of thermal energy, etc. Some of these technologies and equipment are developed and implemented jointly with the Institute of Gas and Technical Thermophysics of the National Academy of Sciences of Ukraine, the European Institute for Sanitation, Safety, Insurance, Equipment and Environmental Protection (SVT eV, Saarbrücken, Germany), E3 International (USA) , E-Energy group (Lithuania), as well as with colleagues in Russia and Belarus.

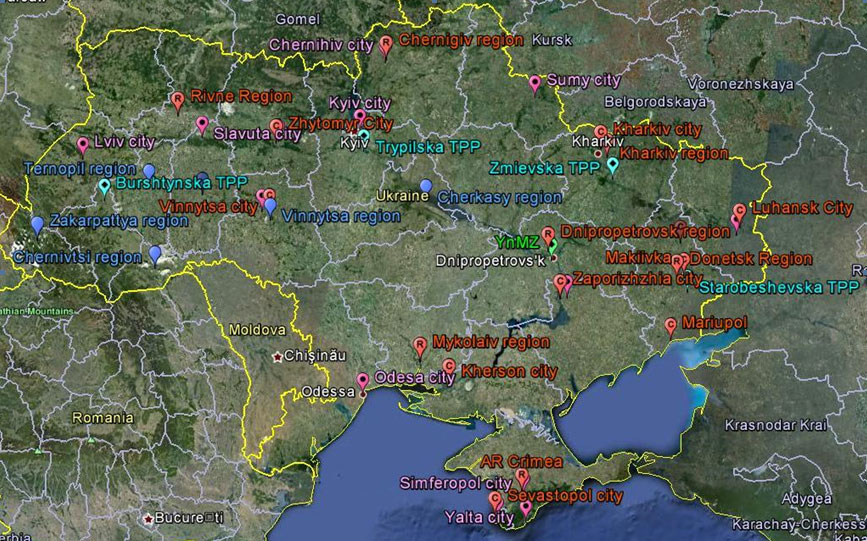

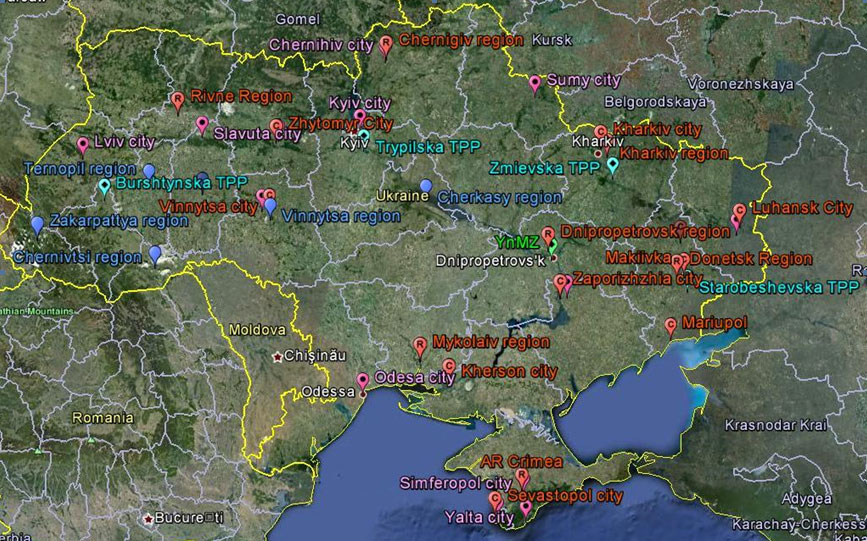

A number of developments of the Institute were recommended by the Ministry of Housing and Communal Services (Ministry of Construction) of Ukraine and implemented in the municipal heat supply systems of the cities of Kyiv, Zhytomyr, Vinnytsia, Sumy, Zaporizhia, Dnipropetrovsk, Kharkiv, Lugansk, Simferopol, Yalta, Sevastopol, Gorlovka, Khmelnytsky, and others. In addition, the Institute’s developments have been implemented at the industrial enterprises of Kyiv, Volyn, Vinnytsia, Chernivtsi, Kharkiv, Chernigov, Lviv, Donetsk and Khmelnytsky regions, as well as Russia, Belarus and Lithuania.

Projects in industry

- Development of technical and working documentation for a water-heating water-tube boiler of 2 MW capacity. 2002-2003.

- Development of technical and working documentation for a water boiler of 0.63 MW capacity. 2004-2005.

- Development of elements of the construction of a water-heating water-tube boiler with the capacity of 1 MW. 2003-2004.

- Development of a set of design documentation for the underarm modernized burner to the boiler TVG-1,5. 2004-2005.

- Development and transfer of documentation for the production of a gas-fired multi-component incomplete pre-mixer burner. 2008

- Completion and transfer of design documentation for gas burner type MPIG with the productivity of 2 MW. 2008

- Development of technical and operational documentation for heat utilization to the boiler KVB-2,0GN. 2005-2008.

- Investigation of the efficiency of heat exchanging surfaces for power plants. 2006

- Development, author’s support of manufacturing and installation, commissioning and commissioning of a heat recovery unit to the boiler TVG-8 of the boiler-house on the street. Belova, 6, m. Chernigov. 2007-2008.

- Completion and transfer of design documentation for equipment for reducing CO2 emissions at the expense of fuel economy: a heat recovery unit for 15,000 m3 / year of exhaust gases. 2008-2009.

- Development, manufacturing, commissioning and commissioning of a contact heat recovery gas cleaning plant to a gas boiler with a volume of exhaust gases up to 15,000 m3 / h. 2005-2006

- Modernization of the boiler PTVM-50 with the installation of an additional bottom burner for boiler productivity increase. 2008-2009.

- Completion of design, manufacturing and installation of additional sub-burner in the boiler PTVM-100. 2006-2009.

- Completion of design, manufacturing and installation of additional sub-burner in the boiler PTVM-50. 2006-2009.

Particularly in the field of dust removal:

- Manufacturing and delivery of four centrifugal filters ЦФ2-6-20 (aspiration of cement mills). 2011 – 2012

- Development of technical solutions for the modernization of the aspiration system of ventilation emissions of USTK-4 Avdeyevka Coke Plant “. 2012

- Development, manufacturing and delivery of two cyclophilic filters TskF-4 (aspiration of technological line of printing of wallpaper). 2012 – 2013.

- Development of outline documentation for the manufacture of two centrifugal filters ЦФ2-6-15,5; author’s supervision over their manufacture and installation, participation in commissioning works (cleaning of flue gases of boilers on solid fuels). 2012

- Development of aspiration system for cement mill 4 × 13.5 m, manufacturing and delivery of equipment for aspiration systems for two cement mills of OJSC “Eurocement-Ukraine”. 2012

Analysis of the state of heat engineering equipment and development of programs for the reconstruction of communal heat supply systems

As part of the work on projects for the reconstruction of district heating systems in the regions and cities of the country, an analysis of the state of the heating equipment of the communal services of the region was carried out through the survey of equipment for boiler houses and heating networks, an assessment of the efficiency of its work on the volume of fuel consumption and productivity. The method of preparation of materials for the region’s municipal utilities equipment database is developed.

Many years of experience of the Institute’s specialists are used to develop numerous projects and regional programs for the reconstruction of municipal heat supply systems in the regions and cities of Ukraine. The specialists of the Institute took part in the development of the Regional programs for the modernization of municipal heat and power engineering in the Autonomous Republic of Crimea and several regions of Ukraine (at the request of regional state administrations).

In 2008, the Institute received a Certificate of Enactment of Energy Audit, which was reissued in 2012. Currently, licensing of this activity has been canceled in Ukraine.

In 2015, the Institute of Industrial Ecology is listed in the register of legal entities that have the right to carry out environmental audits.

- Comprehensive studies of different types of boilers for determining the initial requirements for heat recovery installations. 2013

- Determination of the possibility and appropriateness of installing waste heat of flue gases by boilers with a capacity of more than 4 MW of boiler-houses of KP “Kharkivski teplovi merezhi” and boiler modernization in order to increase their efficiency. 2014-2015

- Determination of possibility and expediency of replacement or further use of boiler equipment of boiler-houses SVP “KIEVS’KI TEPLOVI MEREZHY” PJSC “KYIVENERGO”, on the basis of inspection of technical condition and actual loading of boiler-houses. 2014-2015

- Determination of expediency of replacement, modernization and further use of boiler equipment of POKVPTG “Poltavateploenergo” boiler houses, on the basis of analysis of actual loading of boiler-houses. 2014-2015

- Determination of expediency of replacement, modernization and further use of boiler equipment of boiler-houses of MKP “Khersonteploenergo”, based on analysis of actual loading of boiler-houses. 2014

Joint Implementation Projects

Since 1998, the Institute has been involved with issues related to global climate change, greenhouse gas emission reductions and the Kyoto Protocol to the UN Framework Convention on Climate Change (UNFCCC). According to the Ministry of Housing and Communal Services of Ukraine, the Institute carried out an expert assessment of the potential and opportunities for reducing CO2 emissions from the district heating utilities in Ukraine. The Institute has developed the first draft of the Joint Implementation of Ukraine to reduce greenhouse gas emissions by reducing fuel consumption as a result of the reconstruction of the district heating system in Chernihiv Oblast (2003).

The ability to create joint implementation projects in accordance with the Kyoto Protocol’s mechanisms to the UNFCCC to reduce greenhouse gas emissions by reducing fuel consumption as a result of the reconstruction of communal heat supply systems in Ukraine was ensured through the development of specialists from the Institute of Industrial Ecology LLC, together with experts from the European Institute of Sanitation , safety, insurance, equipment and tools for environmental protection (“SVT eV”, Germany), a specialized methodology for determining the baseline monitoring and monitoring of such projects. This methodology was approved by independent internationally recognized expert organizations, and it was with its use that the design and technical documentation (PDD) of all joint implementation projects for the reduction of greenhouse gas emissions for district heating enterprises in Ukraine was developed.

The Institute developed the JI projects for the reconstruction of district heating systems based on their own methodology for a number of regions (Autonomous Republic of Crimea, Chernihiv, Donetsk, Dnipropetrovsk, Rivne, Kharkiv oblasts) and cities (Kharkiv, Lugansk, Zaporizhia, Vinnytsia, Lutsk, Kyiv, Khmelnytsky, Sevastopol, Makeyevka, Mariupol, Artemivsk, etc.) of Ukraine, as well as projects for the reconstruction of water supply systems in the Autonomous Republic of Crimea, Vinnytsia and Lutsk, on energy efficiency improvement of thermal power stations (Starobeshivsk , Tripoli) with recovery of small hydropower plants in different regions of Ukraine, collection and utilization of landfill gas at the landfill c. Chernigov, the implementation of energy saving equipment and technologies in industry, including the SE “PA Yuzhny Machine-Building Plant. O. M. Makarov “, etc. The PDDs and periodic reports on project implementation monitoring were reviewed by the International TÜV SÜD, Bureau Veritas Certification and TUV Rheinland accredited independent international expert organizations. In total, more than 30 JI projects were developed, of which 15 were already transactions of emission reduction units (about 14 million tons of СО2eq.), As a result of which the enterprises of the country received significant (more than 500 million UAH.) Targeted irreversible investments in their activities.

Joint Implementation projects in the field of housing and communal services

- Reconstruction of the Crimean District Heating System (energy saving measures). 2004 – 2013

http://ji.unfccc.int/JIITLProject/DB/KWHXFPDA7LXPLNZ8XUI7GVPWNUTFTO/details

- Rehabilitation of the District Heating System of Chernihiv Oblast (energy saving measures). 2003 – 2013

http://ji.unfccc.int/JIITLProject/DB/PWS73YAWOKYQ100MP5TH5U7SN06DYO/details

- Reconstruction of the heat supply system in the Donetsk region (energy saving measures). 2005 – 2013

http://ji.unfccc.int/JIITLProject/DB/I71KB95JEW3XSFWSOSHFZG2TA5VUSF/details

- Reconstruction of the heat supply system in the city of Kharkiv (energy saving measures). 2004 – 2013

http://ji.unfccc.int/JIITLProject/DB/D2ZYZ533L116F3KQUPMM1N5HR3FT7S/details

- Reduction of greenhouse gas emissions due to modernization and technical re-equipment of communal enterprises of the Kharkiv region (energy saving measures). 2010-2014

http://ji.unfccc.int/JIITLProject/DB/0O1CLI4C46Y4AVR44SVZ8OCOIMZA04/details

- Reconstruction of the district heating system in the city of Lugansk (energy saving measures). 2006 – 2012

http://ji.unfccc.int/JIITLProject/DB/TZLC02KYS5QMODQVB0RQFN5TRCVLSZ/details

- Rehabilitation of the district heating system in the city of Rivne and Rivne region (energy saving measures). 2004 – 2012

http://ji.unfccc.int/JIITLProject/DB/IJF8S3VKA0GC1U6ZTAOYVHZ30MJVPE/details

- Reconstruction of the heat supply systems of the cities of Makeyevka, Mariupol, Artemivsk, Donetsk region (energy saving measures) 2008 – 2013.

http://ji.unfccc.int/JIITLProject/DB/2EOOY53ZJV102ZQ34Q9PQI9Z1OOQHC/details

- Rehabilitation of the District Heating System of Zaporizhzhya City (Energy Saving Measures) 2008 – 2013.

http://ji.unfccc.int/JIITLProject/DB/VWCOBVYT3RVAZPFQGLXVRSS6E6LZXX/details

- Reconstruction of heat and water supply systems in Vinnytsia region (energy saving measures) 2000 – 2013.

http://ji.unfccc.int/JIITLProject/DB/3GOQ2JT7LF8Q3949RWJLKXQP2E13SA/details

- Reconstruction of heat and water supply systems in the city of Lutsk (energy saving measures) 2012 – 2013.

http://ji.unfccc.int/JIITLProject/DB/41274SYDLJYECOL7HLE77EGRREAHW7/details

- Reconstruction of heat supply systems in Dnipropetrovsk region (energy saving measures) 2003 – 2013.

http://ji.unfccc.int/JIITLProject/DB/FLMFOFASC6G7DUJHBS9RD3WZBMCPOB/details

- Rehabilitation of the District Heating System in Sevastopol (Energy Saving Measures) 2004 – 2010.

- Rehabilitation of the District Heating System in the City of Khmelnitsky (Energy Saving Measures) 2000-2007.

- Rehabilitation of the heat supply system in the city of Kherson (energy saving measures). 2004 – 2009.

- Rehabilitation of the District Heating System in Zhytomyr City (Energy Saving Measures) 2006 – 2009.

- Reconstruction of the district heating system in the city of Odessa (energy saving measures) 2004 – 2009.

- Collection and utilization of landfill gas at the Chernihiv landfill (using landfill gas instead of natural gas at a heating boiler house in the city of Chernihiv) 2006 – 2012.

- Reconstruction of the water supply and drainage system in the Donetsk region (energy saving measures, collection and utilization of waste water from biogas, and the introduction of wind power plants for own power supply). 2008 – 2009

- Reduction of greenhouse gas emissions due to modernization of the objects of the water management complex of the Autonomous Republic of Crimea and the North-Crimean channel (energy saving measures). 2011 – 2014

- Project under the scheme of targeted environmental (green) investments “Insulation of buildings of objects of the budgetary sphere in the Chernihiv region” (energy saving measures). 2008 – 2009

- Project under the scheme of targeted environmental (green) investments “Reconstruction of the plant” Energy “of PJSC” Kyivenerho “with the installation of a line for thermal decontamination (combustion) of waste on the street. Collective, 44 in Darnytskyi district of Kyiv “(co-executor). Joint Implementation project in the field of energy

- Reconstruction of Block No.9 of Zmiyiv TPP of OJSC “Tsentrenergo” 2006-2007.

- Reconstruction and technical re-equipment of Starobeshivska TPP of the Donbasenergo OJSC. 2007-2009.

- Reconstruction and technical re-equipment of the Burshtyn TPP of the Zakhidenergo OJSC. 2008-2009.

- Utilization of Coal Mine Methane at the State Enterprise «Coal Company« Krasnolimanska ». 2008-2009.

- Fuel savings as a result of the commissioning of small hydroelectric power stations. 2007-2009

- Fuel saving at the commissioning of the gas-piston engine-generators of the production of JSC “Pervomaiskdieselmash” for the joint production of electric and thermal energy. 2003-2008

- Implementation of energy-saving equipment and technologies at the State Enterprise “Production Association Southern Machine-Building Plant named after O.M. Makarov “. 2010 – 2013

http://ji.unfccc.int/JIITLProject/DB/DD4691GWX4FPUSTASVDLHMAZRI5O8N/details

Works of the Institute for preparing enterprises for work in conditions of Ukraine's implementation of EU directives

Since 2015, the Institute has been involved with the preparation of the country’s enterprises for work in conditions of Ukraine’s compliance with EU directives in accordance with the Association Agreement between Ukraine and the European Union, in particular Directive 2003/87 / EC on the establishment of a scheme for greenhouse gas emission reductions, in order to ensure the possibility of obtaining permits from the enterprise for greenhouse gas emissions and corresponding participation in the trading system of emission permits as well as Directives 2001/80 / EC “On limitation of emissions of certain pollutants in atm the field of large combustion plants “and 2010/75 / EC” On Industrial Emissions (Integrated Pollution Prevention and Control) “, which regulate the emissions of nitrogen oxides, sulfur oxides and particulates, in order to determine the applicability of the requirements of these Directives to the objects of enterprises and emission reductions to their requirements.

Development and work of the Institute on request of state authorities of Ukraine

The Institute constantly performs work within the framework of the tasks of state bodies, in particular, ministries and state agencies of Ukraine (housing and communal services, science, innovations and informatization, environmental investments, energy efficiency).

According to the tasks of the Ministry (State Committee) on Housing and Communal Services of Ukraine, the Institute of Industrial Ecology has been engaged in many scientific and technical works for the past 16 years, mainly in the field of municipal heat and power engineering.

In particular, in recent years:

- “Development of a methodology for the preparation of projects for the sale of voluntary reductions of greenhouse gas emissions (not under the Kyoto Protocol) due to the reconstruction of communal heat and power facilities”. 2008 year

- “Development of recommendations for the introduction of exhaust gases of cogeneration units in the furnace chamber of the heating boilers”. 2007 year

- “Development of elements of the system for providing internal circulation of flue gas flues in boilers of the type VK (KSVA)”. 2007 year

- “Development of the concept of stabilization of the parameters of boiling air in boilers with a heat output of 1-2 MW of utilities of Ukraine in order to reduce fuel consumption”. 2007 year

- “Development of elements of the design of the new generation boiler burners for boilers TVG-8, KVG-6,5, adapted for a sharp drop in gas pressure in the network.” 2007 year

- “Development of the methodology for calculating greenhouse gas emissions into the air coming from the heat-generating units of municipal heat and power in the combustion of solid fuels”, 2007

- “Development of a formalized methodology for calculating greenhouse gas emissions from heat-generating units of municipal heat and power plants”, 2007

- “Development of an example of the calculation of greenhouse gas emissions entering the atmosphere from the heat-generating units of municipal heat and power in combustion of solid, liquid and gaseous fuels”, 2007

- “Development of technical solutions for the reconstruction of water-heating boilers of high capacity (more than 50 Gcal / hour)”, 2005

- “Development of the Procedure for the Preparation of Joint Implementation Projects on Reducing GHG Emissions by Utility Companies”, 2005

- “Development of methodological recommendations for the selection of heat supply facilities for the implementation of cogeneration units”, 2005

- “Analysis and scientific assessment of the implementation options for the energy balance of settlements of cogeneration units on the basis of existing heating boilers”, 2005

- “Development of technology and design documentation for a boiler with a capacity of 1 MW for burning peat at boiler houses of municipal heat and power engineering”, 2004

- “Rehabilitation and commissioning of experimental experimental heat utilization at the boiler KV-GM-10”, 2004

- “Evaluation of the efficiency of the reconstruction of heating networks by: (i) repairing or replacing the isolation of tubing pipes with the use of new insulating materials developed and produced in Ukraine; (II) replacement of pipes for pre-insulated, made in Ukraine and abroad “, 2000

- “Expert assessment of the potential and possibilities of reducing СО2 emissions to the atmosphere by the enterprises of district heating of Ukraine”, 1999.

Work has also been carried out in recent years:

At the request of the Ministry of Fuel and Energy of Ukraine:

- “Development of a standard monitoring report on emissions of greenhouse gases into the atmosphere and their possible reduction for energy generating companies of the Ministry of Fuel and Energy of Ukraine” (co-executor). 2008

- “Development of scientific and technical documentation of a typical Pilot Project for the modernization of the TPP, in accordance with the requirements of the United Nations Joint Implementation Supervisory Committee” (co-executor). 2007

At the request of the Ministry of Education and Science of Ukraine:

- “Development of the concept and thermal scheme of heating of liquid fuel in boiler houses using solar energy, in accordance with the conditions of. Snake “(co-executor). 2008 – 2009

- “Establishment of a system of preparation of joint implementation projects aimed at reducing greenhouse gas emissions in industry and utilities”. 2003 – 2004

- “Integrated technology for increasing the efficiency of fuel use and reducing emissions of toxic substances into the atmosphere by industrial and heating boiler houses of Ukraine”, 1998-2000.

At the request of the National Agency of Ukraine for the Effective Use of Energy Resources (NAER):

- “Development of methodological recommendations for assessing the efficiency of the implementation of cogeneration equipment”. 2006

At the request of the State Agency for Science, Innovation and Informatization of Ukraine:

- “Development of the draft simplified national procedure of Ukraine for the registration and transfer to investors of GHG emission reduction units received by joint implementation projects” (co-executor). 2011 – 2012

Projects for international financial and credit institutions

World Bank

Feasibility study “Reconstruction of heat supply facilities of SE” Dneproteploenergo “DOR and their dispatching”. 2014 (co-executor)

The geographic location of the Institute’s work in the field of energy efficiency in Ukraine